Safety and Operations

Safety is a core value at MGE and it is embraced by our employees. When it comes to safety, every person and every company can always improve upon their safety performance. That is why we embrace a philosophy of continuous improvement.

Business continuity during COVID-19

On March 24, 2020, Wisconsin Gov. Tony Evers issued a Safer at Home order requiring people in Wisconsin to remain at home, with some exceptions. Under the order, MGE was deemed an essential infrastructure company. MGE developed a framework to guide our decisions regarding the criticality of operations work to be completed and the manner in which it should occur safely.

We have always embraced our responsibility to provide our customers with safe and reliable energy, which is even more important during a pandemic. While we made adjustments to work routines and schedules, we never stopped performing the work required to fulfill our obligation to ensure the safe and reliable operation of our electric and natural gas systems to maintain safe and reliable service to our customers. We also continued work required to maintain other businesses and organizations permitted to continue operations under the governor’s order. Read more about MGE’s COVID-19 response.

We Power Safety

In 2014, MGE launched a corporate safety commitment to improve our safety culture and begin MGE’s journey to safety excellence. Our Safety Steering Team meets bimonthly to examine safety topics and to identify and to prioritize continuous improvement opportunities.

Our employees have taken the lead through their continuous improvement efforts to make MGE a safer place to work. Our employee-led Continuous Improvement Teams (CI Teams) are one example.

MGE’s safety vision statement was developed by one of our employee-led CI Teams. The team drafted a statement of safety values that encompasses the business of MGE and creates a positive message that all MGE employees can adopt:

As MGE employees, we power our own safety and the safety of those we work with to ensure everyone goes home safely. Our goal is zero injuries. Every day. Everywhere.

Our safety vision statement—we power safety—is highly visible throughout our organization.

In 2018 and 2019, MGE had back-to-back, record-setting safety achievements. In 2019, we recorded our lowest recordable incident rate and our second-lowest lost-time incident rate since we started keeping records in 1971. Our all-time low lost-time incident rate was recorded in 2018.

2019 Continuous Improvement Teams

In 2019, we had two CI Teams working to build on our historic safety success in 2018. The teams focused on risk behaviors at work and office safety.

Risk Team Six

Our sixth CI Team, Risk Team Six, was formed to gain an understanding of risk behaviors, including what risks are taken by employees and why, and to determine how to mitigate risks. The team conducted 28 focus groups with over 90% of the workforce. Employees acknowledged some calculated risks are taken due to convenience, complacency and other influencers. Risk Team Six uncovered the key influencers that may cause employees to take risks, identified existing tools for managing risk and developed recommendations for mitigating risk.

Motivational safety speaker visits MGE

As part of the team’s work in 2019, Risk Team Six arranged for motivational safety speaker Brad Livingston to visit MGE. Livingston shared his powerful “You Think It Can’t Happen to You” presentation as part of our first-ever companywide safety meeting, which included operations and office personnel. This opportunity was arranged to help employees fully understand the possible effects of taking an unnecessary risk at work or in any part of their life. More than 500 employees attended the presentation at multiple MGE facilities over a two-week period.

Livingston worked for a natural gas company in 1991 when he was severely injured in back-to-back tank explosions that took the life of his coworker and nearly ended his. As Livingston explained, the explosions were completely preventable and never should have happened. His presentation served as an impactful reminder that each of us is responsible for our actions. We are accountable to each other whether performing skilled work on the job, driving in a car, working on a hobby at home or enjoying a recreational activity.

Office Safety Team

The Office Safety Team developed a strategy and supporting tactics to ensure office personnel remain informed, aware and involved in safety activities that are relevant and meaningful and that add value. This is being accomplished in a number of ways, including through safety meetings focused on topics relevant to office personnel, such as understanding the importance of proper ergonomics; utilizing and enhancing some of the wellness tools already in place for employees, such as access to our workplace injury prevention trainers; and developing an employee reference guide that details what to do in certain emergency situations. In early 2020, the Office Safety Team organized ergonomics workshops that were attended by more than 120 employees.

Enhanced safety protocols related to the COVID-19 response interrupted 2020 CI Team planning; however, the Safety Steering Team expects to resume CI Team efforts in 2021.

Near-miss/good catch

MGE’s near-miss/good catch reporting process continues to be successful. This proactive process, developed by an employee-led CI Team in 2017, is designed to encourage reporting that identifies, documents, addresses and allows everyone to learn from safety impacts. The reporting process establishes accountability at all levels of the company to ensure it is implemented in a safe, no-blame environment.

In three years of using the near-miss/good catch process, more than 150 near-miss and good catch reports have been filed. Sharing near-miss/good catch reports with employees is designed to help all employees learn about safety issues and to help prevent incidents, both of which serve to improve our safety culture and collective performance.

Employee wellness

MGE offers employees a comprehensive wellness program. Our Healthy Rewards program includes exercise classes led by professional instructors; a fitness room with exercise equipment; educational sessions on nutrition, wellness, weight control and smoking cessation; expertise available from the Mayo Clinic through the managewell.com website; biometric screenings; health assessments; and annual flu shots. These offerings promote healthy living for our employees. During the COVID-19 pandemic, wellness classes and sessions have been offered to employees virtually.

Preventing sprains and strains

MGE supports employees through a partnership with a workplace injury prevention sports medicine provider that employs athletic trainers. These trainers teach employees how to properly warm up and stretch before performing physically demanding work and how to perform ergonomic assessments. This partnership was launched to address sprain and strain prevention proactively and before medical treatment becomes necessary.

We recognize that our operations employees are industrial athletes. Like a professional athlete, working athletes need the highest level of support and care.

With easy access to the athletic trainers, employees are able to get the coaching they need from someone who understands the type of work they do and the type of injuries they may experience. Our trainers can help with early intervention to minimize and even eliminate those injuries.

In 2019, the program expanded to include MGE’s office employees. In 2019, there were nearly 1,500 one-on-one meetings between an employee and trainer, and nearly 5,500 employee contacts occurred in 651 group sessions with employees and trainers.

From January through June 2020, there were 361 one-on-one meetings between employee and trainer, and nearly 1,500 employee contacts occurred in 172 group sessions. In April 2020, during the COVID-19 pandemic, we transitioned to virtual sessions, allowing employees to continue meeting with trainers.

As a result of this partnership, sprain and strain injuries requiring medical treatment have fallen dramatically. It’s a positive program for employees and the company, reducing injuries and producing savings in the workers’ compensation fund.

All hazards response

Whether it’s a natural disaster or a man-made disaster, MGE has plans in place to prevent and mitigate damage. Having a well-defined and practiced All Hazards Response Plan (AHRP) is critical to managing and responding appropriately to emergency situations. MGE’s AHRP encompasses everything from storm response to cyberattacks.

Storm Response Plan

MGE takes seriously the risk from severe weather. We have a companywide Storm Response Plan (SRP), which serves as our guide or framework for rapid, effective response to emergencies caused by extreme weather events.

The Incident Commander leads the SRP functions and is supported by Section Chiefs who are responsible for running the major functional sections within the SRP. Some of those functions include assessing damage, ordering supplies and managing mutual assistance crews from other utilities as well as responding to media and customers experiencing an outage or other service-related issues from the event.

MGE participates in disaster recovery planning

Security is a priority at MGE—cybersecurity and physical security. We are committed to protecting our networks and data from unauthorized access and ensuring safe, reliable service for customers. We also are committed to working proactively with partners to ensure a plan is in place for prioritizing customers’ electric needs if a limited supply of electricity is available as the result of security incidents.

MGE and Dane County Emergency Management cohosted a disaster recovery planning exercise sponsored by the North American Electric Reliability Corporation (NERC) in 2019. GridEx V participants included the City of Madison police and fire departments, Madison Metropolitan Sewerage District, Madison Water Utility, University of Wisconsin, UnityPoint Health and UW Health.

The exercise scenario called for a severe shortage of electricity and the need to decide how a limited amount of power would be used. Participants had to think about how power supports emergency management functions at a more granular level and then consider how to prioritize those electric needs during a crisis.

Incident Command Structure activated during COVID-19

The Incident Command Structure (ICS), which is the basis for all responses under the AHRP, was activated early on in MGE’s COVID-19 response. The ICS coordinated the diverse aspects of our response to ensure measures were in place to minimize COVID-19 exposure by MGE employees. By mid-March, the MGE lobby was closed, employee access was restricted to certain areas in various facilities, additional daily cleaning occurred at all MGE facilities and many employees and entire teams began working from home. These were just a few of the numerous steps taken to protect employees and customers. Read more about the measures taken.

Working to keep our communities safe

In addition to the safety of our employees, the safety of our customers also is a top priority. We strive to keep customers well informed about the potential dangers of electricity and natural gas and what to do in an emergency, using electric and natural gas safety advertising and information included with our bills, on our social media channels and on mge.com.

Safety in the classroom

MGE partners with schools throughout our service territory and offers a wide array of classroom lessons, including electric and natural gas safety. From curriculum supporting materials to visiting the classroom to share safety tips, MGE provides important energy safety lessons to students.

One of the most popular programs is MGE’s Switch to Safety. In addition to discussing gas safety, an MGE representative uses a tabletop electric safety model to illustrate and simulate potentially dangerous outdoor electric safety situations.

First responder training

MGE works closely with police and firefighters who respond to emergencies within our service territory. MGE’s Electric and Gas Operations departments conduct safety training with first responders within the communities we serve. MGE also routinely conducts drills with the Madison Fire Department at both of our Madison power plants.

Safety Saturday

MGE is a proud sponsor of the Madison Fire Department’s annual Safety Saturday event. MGE employees from Electric Construction and Operations, Gas Construction and Operations, and Corporate Communications staff a display to share important gas and electric safety information.

Safety Saturday uses interactive displays and exhibits to educate parents, children and the public on ways to make safe decisions, to prevent injuries and to encourage the use of safety devices such as seat belts, bike helmets, smoke alarms and carbon monoxide detectors.

Due to COVID-19, Safety Saturday was cancelled in 2020.

Natural gas safety and sustainability

Ensuring reliability and safety are top priorities at MGE along with protecting our environment. We are committed to continuing to provide the high level of service our customers expect.

Industry leader in emergency response

When notified of a potential natural gas emergency, MGE crews continue to earn high marks. Again in 2019, our total response time ranks in the top 20% of a nationwide industry survey.

This ranking is reflective of our dedicated employees who always put customer safety first and understand what it means to serve as your community energy company. It also shows what a good process MGE has in place—from when the call comes into the Customer Center to when our employees arrive on-site.

Suppliers’ commitment to sustainability

MGE contracts with two natural gas transmission companies, Northern Natural and ANR Pipeline Company, owned by TC Energy.

Both of these companies, as part of their sustainability commitments, are part of the ONE Future Coalition. ONE Future is the trade name for “Our Nation’s Energy Future Coalition, Inc.” This group of natural gas companies works together to voluntarily reduce methane emissions across the natural gas supply chain.

TC Energy also is a founding partner in the EPA’s Natural Gas STAR Methane Challenge Program, which launched in 2016. Partners in this voluntary program report systemic and comprehensive actions to reduce methane emissions as part of efforts to enhance transparency in the industry.

Sustainability benchmarking and partnerships

MGE is committed to reducing environmental impacts across all areas of the company. MGE voluntarily participates in statewide environmental performance programs and various industry sustainability and benchmarking groups.

Green Masters Program

In 2020, MGE earned the Green Master designation for the seventh consecutive year from the Wisconsin Sustainable Business Council. Only the top 20% of applying companies receive the Green Master designation.

The independent, points-based benchmarking program evaluates applicants in nine key areas: energy, climate change, water, waste, transportation, supply chain, community outreach, workforce and governance. MGE was the first utility to be awarded the distinction in 2014.

Energy Sustainability Interest Group

MGE partners with the Electric Power Research Institute (EPRI) in a number of areas, including the Energy Sustainability Interest Group (ESIG). The largest sustainability-focused group of its kind in the electric power industry, ESIG:

- Provides a collaborative industry forum for electric power companies to discuss sustainability issues.

- Conducts focused technical research and develops specific tools to support sustainability program development.

- Tackles the challenge of identifying and understanding sustainability issues, goals, metrics and disclosure.

- Facilitates stakeholder engagement.

- Informs sustainability reporting initiatives.

ESIG projects focus on priority issues, goals, metrics and sustainability communication for the electric power industry and its stakeholders. The project work may be utilized by group members to inform the development of their own sustainability programs and initiatives. Launched in 2008, ESIG has more than 40 members from the electric power industry.

Sustainability benchmarking

In 2019, EPRI marked its sixth year of an ongoing effort to identify and understand metrics appropriate for benchmarking the performance of electric power companies on their priority sustainability issues. MGE has participated in this EPRI benchmarking since it began in 2014.

The Sustainability Benchmarking for Utilities project is conducted in collaboration with the previously mentioned ESIG and subject matter experts throughout EPRI. The project work is designed to advance technical research around what a sustainable electric power company looks like and how it can support the sustainable generation, delivery and utilization of electric power to customers.

Transparency and disclosure

To advance further transparency and disclosure in our operations and governance, MGE also participates in the Edison Electric Institute’s (EEI) environmental, social, sustainability-related reporting template. The voluntary, industry-specific template includes both qualitative and quantitative information, such as generation and emissions data. Our EEI templates are available at mgeenergy.com/environment.

Task Force on Climate-related Financial Disclosures

Our report is organized to be consistent with the disclosure recommendations identified by the Task Force on Climate-related Financial Disclosures (TCFD) to help customers, investors and other stakeholders better understand our strategies, challenges and opportunities.

The company has reviewed the TCFD recommendations, performed an analysis of its disclosures relative to the TCFD recommendations and determined that MGE’s disclosures are consistent with the TCFD guidance and recommendations.

Protecting our natural resources

MGE takes steps to protect our natural resources. This means doing our part to help improve waterways, preserve the natural beauty of our communities and protect wildlife habitats.

Erosion control

We are committed to implementing proper erosion control methods at all work sites. This minimizes the likelihood of soil being washed out of a site. We track permits and inspections and have a committee that reviews new regulations, field techniques and technologies to ensure we effectively manage our erosion-control strategies.

Stormwater management

Pollutants transported in stormwater are harmful to lakes, rivers, wetlands and waterways. MGE implements measures to protect our water bodies. For example, MGE’s downtown parking lot has a stormwater filtration system. This system cleans stormwater before it drains into nearby Lake Monona. This system is effective in reducing pollutants such as petroleum compounds, sediment and phosphorus.

Phosphorus reduction in local lakes

Another way MGE supports clean lakes is through Yahara WINS. This collaborative water cleanup effort began as a pilot and expanded to a 20-year program to reduce phosphorus in our watershed. MGE supports this project financially through the MGE Foundation and by serving on its technical advisory board. A collaborative approach pools the resources and expertise of community partners. It employs the strategy of watershed adaptive management in which all sources of phosphorus pollution are addressed together to meet water quality goals.

The program prevented more than 50,000 pounds of phosphorus from reaching surface waters in 2019.

Invasive species

Invasive species and non-native plants adversely affect areas where they spread. They also may pose a risk to human health. Invasive species can be found in forests, grasslands, wetlands, lakes and rivers.

Working together with MGE’s Environmental Affairs department, Electric and Gas Operations employees are trained on how to identify invasive species in MGE’s service area, plan work around them, avoid contact and follow procedures for post-work cleanup.

The combination of interdepartmental coordination and formal systems for dealing with invasive species and non-native plants helps MGE stay in compliance, minimize impacts and avoid project shutdowns.

Solar powers corporate office

Nearly 450 solar panels on our corporate office in Madison, Wis., generate about 10% of the energy needed annually to power the facility. The array, along with 52 panels in our visitor parking lot, represent another step in our ongoing path toward greater sustainability throughout our operations.

In addition, MGE’s 2,000-square-foot office building in Prairie du Chien, Wis., also has 20 solar panels on the roof capable of producing about 5.3 kilowatts of energy.

Bottle filling stations and filtration systems

Throughout our facilities, MGE has 16 water bottle filling stations and filtration systems for employees to reduce the use of plastic bottles. In the eight years since the first one was installed, MGE employees have avoided using almost 600,000 disposable plastic bottles.

Eliminating waste with e-records

MGE’s E-records Center allows employees to submit electronic documents to be stored as records rather than keeping paper copies. Over time, this will reduce our volume of paper. This environmentally friendly option also frees up physical storage space.

Paperless billing

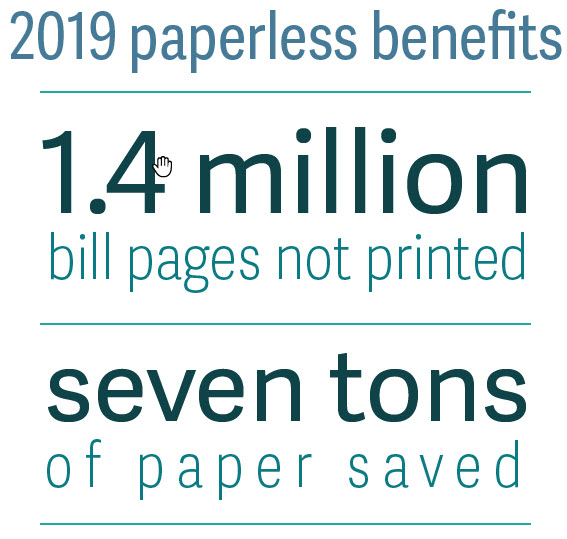

MGE launched My Bill Pay, an improved online billing and payment system, for customers in 2016. Online billing and payment is a “win-win” for customers and companies. Studies find customers are more satisfied when viewing and paying their bills electronically. Companies benefit by realizing paper and postage savings from not having to print and mail paper bills.

Based on the number of customer accounts signed up for paperless billing as of June 2020, more than 1.4 million bill pages are not printed each year, which saves:

- More than 2,800 reams of paper per year.

- More than 14,000 pounds, or seven tons, of paper per year.

The estimated annualized savings from our paperless billing adoption is more than $300,000.

Supply chain and waste management

Successful waste management requires a solid recycling program. We encourage employees to make smart choices about the environment. That includes supporting our recycling and waste-reduction efforts every day. We work to conserve, recycle and manage waste efficiently.

Reduce-reuse-recycle

Our all-in-one recycling method includes paper products, glass, plastic and aluminum. We also recycle various metals and other scrap materials left over from field work. Our computing equipment and supplies are sent to an e-Stewards certified company for recycling or reuse, and our alkaline batteries go to a vendor who recovers steel and zinc. A Continuous Improvement Sustainability Team is currently in the process of reviewing our battery recycling program. Additionally, a local vendor takes our wood pallets, recycling them into mulch.

Earth-friendly paint option

Historically, non-recyclable aerosol paint cans have been used to mark underground gas and electric facilities. Aerosol cans push out the paint using a propellent, which is often hazardous. Aerosol cans also are under pressure, which causes them to be considered hazardous waste even if the paint in the can is not hazardous.

MGE has been working to find earth-friendly paint options. MGE’s first test product, a bagged paint technology that offered several benefits, also had some drawbacks. So we tested a second product that creates less waste, saves money and allows for steel recycling and reuse of the nozzle.

The overall design of the paint container leads to the reduced waste. Typical designs have two main problems. They leave a small amount of product in the bottom that the aerosol can’t dispel and the aerosol nozzle tends to get clogged and/or broken. The new can is bigger, which means fewer change-outs, leading to cost savings. And, the new paint product has been more consistent while marking gas and electric facilities, which translates to better efficiency for the locators in the field. There’s also less waste with the new cans, and they empty out completely so we can recycle them.

Supplier proximity and diversity

MGE is committed to supplier diversity. Our goal is to ensure that equal opportunities exist for all small businesses, women-owned businesses and minority-owned business enterprises.

MGE’s corporate policy is to buy locally. We will give preference to Wisconsin manufacturers and distributors. Local purchases support the local economy and are typically more environmentally friendly. When it is time to purchase goods needed to run our company, we review our supplier database and buy from local vendors when possible and cost-effective. Many of the materials and equipment that utilities need are highly specialized; however, we buy U.S. products whenever possible.

Comprehensive risk minimization

MGE has transitioned to a new software system for use in risk minimization. MGE’s environmental team oversees hundreds of routine monitoring, record- keeping and reporting tasks, some of which occur every week. In the past, these were tracked on multiple different servers to manage the data and deadlines as the tasks were assigned to and tracked for employees across several departments.

In 2019, MGE began using the new software, which replaced all the old servers and more with one comprehensive Environmental Management Information System (EMIS). The new EMIS makes it significantly easier to see and track the different tasks. For example, inspections in the field are now done and saved electronically, which means the data can be retrieved instantly.

The new system provides MGE with better and quicker access to the status of compliance activities and improved information for resource planning. It also improves our reporting performance. This leads to more efficient use of time, better alignment of information management processes and simplified training for turnover or responsibility transfers.

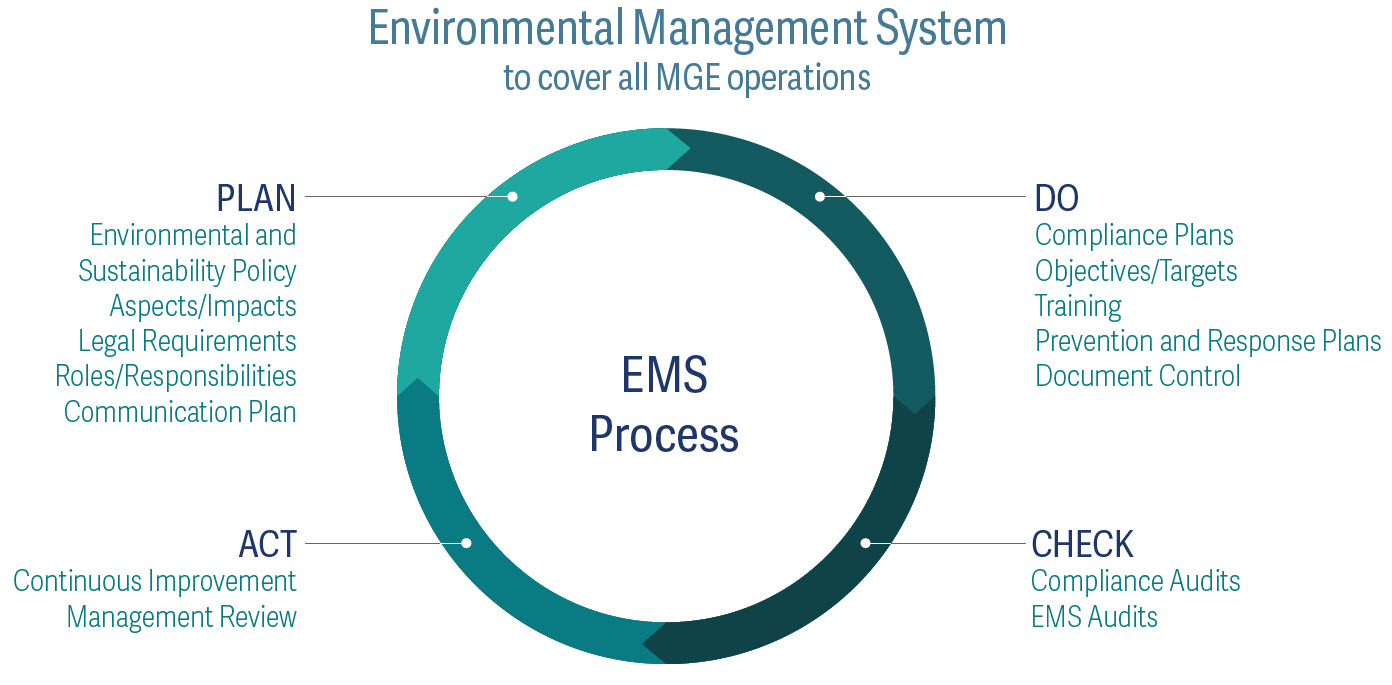

Environmental Management System

In 2017, MGE expanded the scope of our renewed five-year contract with the Wisconsin Department of Natural Resources for Green Tier certification, which recognizes environmental leadership. Our primary goal in the expanded contract is to cover all MGE operations under our Environmental Management System (EMS). An EMS is a continuous improvement process that evaluates, prioritizes and manages environmental risks.

MGE previously used an EMS at our Blount Generating Station. The expanded scope of our EMS captures environmental improvements across the company and further demonstrates our commitment to goal- setting and environmental accountability.

As part of our EMS expansion, MGE’s Sustainability Steering Team developed environmental goals, targets and action plans for 2020-2021. These were informed by MGE’s Environmental and Sustainability Policy and work done by staff in our operations areas to evaluate and rank MGE’s operational environmental impacts.

Our 2020-2021 Environmental Management System goals

- Implement a corporate expansion of MGE’s EMS that is designed to meet Wisconsin Green Tier requirements.

- Conduct a risk review of MGE’s environmental emergency response plans looking at risk to waterways, human health and sensitive environmental features.

- Add environmental emergencies to the corporate All Hazards Response planning process.

- Complete removal and replacement of all PCB-contaminated transformers from service by 2021.

- Continue to implement the Fleet Alternative Vehicle Policy that evaluates new MGE vehicles when it is operationally prudent. Review how we can measure and track environmental impacts.

- Continue to convert to LED lighting at MGE facilities where feasible in 2020. Continue energy efficiency projects during building upgrades and track estimated energy savings from these projects.

Teams have been developed to ensure that we have action plans in place to meet these goals.